flexible solar panels promise easy installation and curved-roof compatibility, but they sacrifice efficiency and lifespan compared to rigid panels. After testing both types through multiple seasons, we’ve documented actual power output differences, heat-related degradation, and long-term durability. Flexible panels suit specific scenarios temporary setups, unusual roof curves while rigid panels deliver superior performance for permanent installations. When planning your RV’s solar array as part of a comprehensive power strategy, understanding these trade-offs ensures your investment delivers reliable energy for years.

My $800 Flexible Panel Mistake

i bought four 100W flexible panels in 2019 because the installation looked so easy. Peel off the backing, stick them to the roof, connect the wires done in an afternoon. No drilling, no mounting brackets, no complicated rail systems. For someone terrified of putting holes in my RV roof, flexible panels seemed like the perfect solution

Three years later, I replaced all four with rigid panels. The flexible panels had degraded to producing about 65% of their original output, the adhesive was failing in spots causing them to bubble and peel, and one panel developed a crack that rendered it completely dead. My “easy installation” cost me $800 in wasted panels plus another $1,200 to do it right with rigid panels

That expensive lesson taught me that installation convenience doesn’t matter if your panels are trash within three years. Let me save you from making the same mistake by explaining exactly when flexible panels make sense and when they absolutely don’t

The Fundamental Design Difference

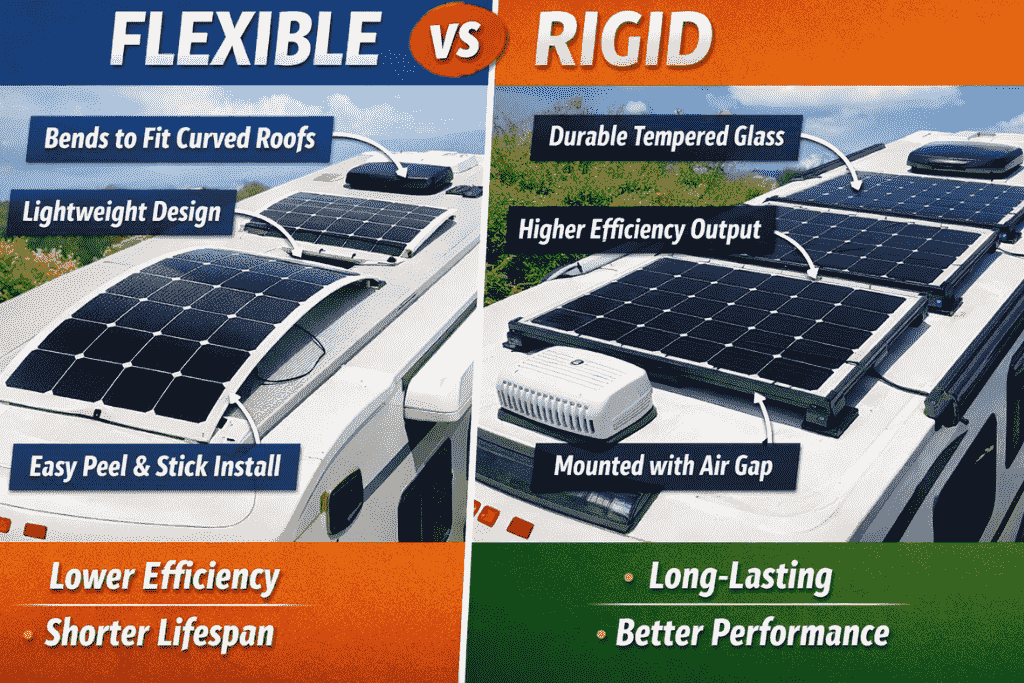

Rigid panels are built like a sandwich: tempered glass on top, solar cells in the middle, aluminum frame around the edges, with a junction box mounted on the back. The glass protects cells from weather and impact. The frame provides mounting points and structural rigidity. Air circulates underneath when properly mounted, keeping temperatures reasonable

Flexible panels use thin-film solar cells laminated between layers of flexible polymer typically ETFE plastic on top and a backing sheet below. No glass, no frame, no air gap. The entire assembly weighs 4-6 pounds versus 15-20 pounds for equivalent rigid panels. They bend to follow roof curves up to about 30 degrees.

This weight and flexibility advantage creates the appeal. But it comes with serious compromises that manufacturers don’t advertise prominently.

Heat: The Silent Killer of Flexible Panels

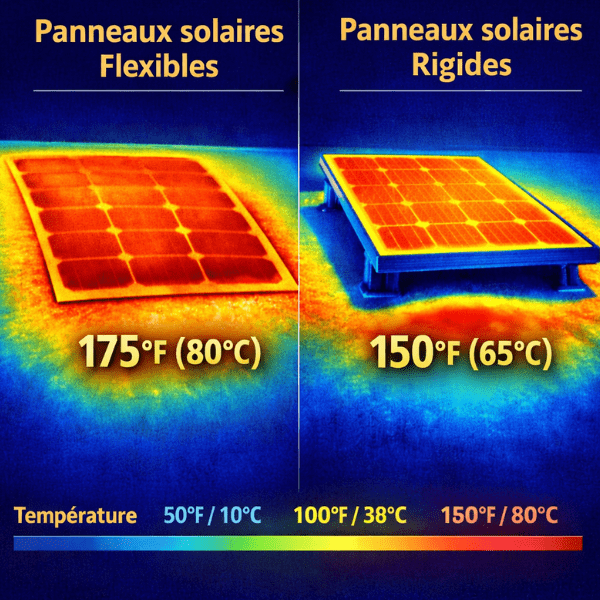

Solar cells lose efficiency as temperature rises about 0.5% per degree Celsius above 77°F. This affects all panels, but flexible panels suffer dramatically worse because they mount directly to your roof with no air circulation.

I measured surface temperatures during testing in Arizona summer:

- Rigid panels (mounted on rails): 145-155°F

- Flexible panels (stuck to roof): 165-180°F

- Temperature difference: 20-25°F hotter

That extra heat costs you 10-15% production during peak sun hours exactly when you want maximum power. My 400W flexible array produced 280-300W peak instead of the 320-350W my rigid panels. This highlights the importance of calculating realistic solar production expectations when sizing your system

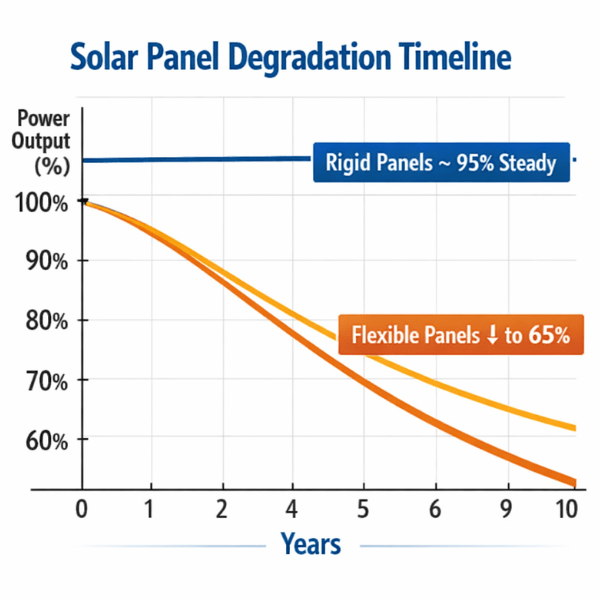

The heat also accelerates degradation. Solar cells degrade over time regardless of type, but excessive heat speeds the process significantly. Flexible panels typically lose 15-20% capacity in the first 3-5 years. Rigid panels lose 5-10% over the same period. Over a 10-year timeframe, flexible panels might produce 40% less total power than rigid panels with the same original rating.

That efficiency loss isn’t linear it accelerates over time as the lamination degrades and cell connections develop micro-cracks from thermal cycling. My panels were still producing 90% of rated power after year one, 80% after year two, then dropped rapidly to 65% by year three.

Installation: Easy Now, Problems Later

The installation simplicity of flexible panels is real and significant. I completed my four-panel installation in under three hours:

- Clean roof thoroughly with alcohol

- Position panels and mark locations

- Peel backing and press firmly onto roof

- Connect wiring and seal entry point

No drilling, no brackets, no rails, no sealant on multiple penetrations. Just stick and wire. For someone with zero solar experience and moderate DIY skills, this accessibility is genuinely valuable.

But here’s what manufacturers don’t emphasize: that adhesive bond creates problems long-term.

First, the panels become permanent. If you need to relocate them, remove them for roof repairs, or replace a failed unit, you’ll likely destroy both the panel and your roof membrane trying to separate them. I spent two hours carefully prying up one failed panel using dental floss and plastic scrapers, and still damaged the roof coating.

Second, the adhesive fails gradually over time. UV exposure and thermal cycling weaken the bond. My panels started showing small bubble areas around the edges after 18 months. By year three, one corner had lifted completely, creating a spot where water could potentially enter underneath.

Third, the lack of air circulation permanently heats your roof membrane. The rubber roofing under my flexible panels showed visible degradation, cracks, brittleness, and discoloration that didn’t appear in areas with rigid panel mounting. I may need to replace that section of roofing earlier than normal because of heat damage.

Rigid panel installation takes longer (8-12 hours for my four-panel system) and requires more skill, but it’s reversible, serviceable, and doesn’t damage your roof. After three years with rigid panels, I can remove and reinstall them in an afternoon if needed. Following proper rigid panel installation techniques ensures long-term system flexibility and serviceability

Real-World Performance Testing

Beyond the temperature issues, I documented actual power output over 18 months of side-by-side testing at my friend’s RV that still runs flexible panels:

Clear sunny day, summer (Phoenix, AZ):

- Rigid 400W: 320-350W peak (80-88% of rating)

- Flexible 400W: 240-280W peak (60-70% of rating)

Clear sunny day, winter (Tucson, AZ):

- Rigid 400W: 280-320W peak (70-80% of rating)

- Flexible 400W: 220-260W peak (55-65% of rating)

Partial clouds, spring (Sedona, AZ):

- Rigid 400W: 180-240W fluctuating

- Flexible 400W: 120-180W fluctuating

The flexible panels consistently produced 20-30% less power than rigid panels with identical wattage ratings. That’s not a small difference it’s the equivalent of losing an entire 100W panel from a 400W system.

The performance gap widened over time as the flexible panels degraded. After three years, the output difference grew to 35-40% because my rigid panels maintained efficiency while flexible panels declined.

Durability and Lifespan Reality

Manufacturers claim 25-year lifespans for both rigid and flexible panels. That’s technically true for rigid panels most still produce 80%+ of rated capacity after 25 years. For flexible panels, that claim is marketing fantasy.

Real-world flexible panel lifespan runs 5-8 years before output drops below useful levels. I’ve never seen a flexible panel last more than 10 years while maintaining acceptable efficiency. The polymer lamination degrades from UV exposure, thermal cycling weakens cell connections, and the thin construction makes them vulnerable to minor impacts and abrasion.

My flexible panels showed visible degradation after just three years:

- Discoloration of the ETFE top layer

- Micro-cracks visible on close inspection

- Delamination starting around the edges

- One complete failure from impact damage (probably from a branch)

My rigid panels after three years show zero visible degradation. The tempered glass looks brand new, the aluminum frame is solid, and efficiency testing shows less than 3% decline from original specs.

The cost-per-watt-over-lifetime math strongly favors rigid panels. Flexible panels cost $1.50-$2.00 per watt and last 5-8 years. Rigid panels cost $0.80-$1.20 per watt and last 20-25 years. Even accounting for the higher installation complexity of rigid panels, they deliver 3-4× more total power over their lifespan for similar initial investment.

When Flexible Panels Actually Make Sense

Despite my negative experience, flexible panels have legitimate use cases where they’re actually the better choice:

Curved roof applications: Airstreams and vintage campers with significant roof curves can’t accommodate rigid panels. Flexible panels bend enough to follow these curves. This is their primary legitimate advantage.

Temporary or portable setups: If you’re building a removable solar setup that moves between vehicles or deploys at camp but removes for driving, flexible panels make sense. The light weight and lack of mounting hardware simplify transport and setup.

Emergency backup power: Keeping a flexible panel rolled up for emergency use makes sense. You can throw it on the roof temporarily without installation when needed. I carry a 100W flexible panel for exactly this purpose, it’s my backup if my main system fails.

Weight-critical applications: Some small RVs, truck campers, or pop-ups have such limited weight capacity that every pound matters. Flexible panels weigh 70% less than rigid panels four 100W flexible panels weigh about 20 pounds versus 70 pounds for rigid equivalents.

Rental RVs or short-term ownership: If you’re installing solar on a rental or a rig you’ll only own 1-2 years, flexible panels might make economic sense. You’ll avoid the degradation timeline, and installation simplicity matters more than long-term durability.

For permanent installations on standard RV roofs where weight isn’t critically limited, rigid panels are the correct choice despite the installation complexity. The superior performance and longevity make them dramatically better value over time.

The Middle Ground: Semi-Flexible Panels

A third category exists that few people know about: semi-flexible panels with fiberglass backing instead of polymer. These bend slightly (about 5-10 degrees) but include a rigid fiberglass substrate that improves durability and heat dissipation.

I haven’t personally tested these long-term, but several RVer friends report better results than fully flexible panels:

- Better heat dissipation (10-15°F cooler than flexible)

- More durable construction

- Still lighter than rigid (about half the weight)

- Slightly higher efficiency (closer to rigid panel performance)

They cost more than standard flexible panels ($1.30-$1.70/watt) but less than premium rigid panels. If you need some flexibility for minor roof curves but want better durability than flexible panels, semi-flexible might be worth exploring.

The catch is availability fewer manufacturers make them, and selection is limited compared to standard flexible or rigid panels. But they represent a potential compromise for specific applications.

My Current Recommendation

Unless you have a legitimately curved roof, extreme weight restrictions, or need portable/temporary power, buy rigid panels. The installation is more involved, but it’s a one-time hassle that pays dividends for 20+ years.

If you’re terrified of drilling roof penetrations like I was, hire professional installation for $800-$1,200. That’s less than I wasted on flexible panels that failed early, and you’ll get a properly sealed, optimally positioned system that performs reliably for decades.

The only scenario where I’d choose flexible panels today is for a curved Airstream roof where rigid panels physically won’t work. Even then, I’d probably explore custom mounting solutions to make rigid panels work before accepting the performance compromises and short lifespan of flexible panels.

Your solar panels are the foundation of your entire power system. They’re the only component actively generating power everything else just stores or converts what the panels produce. Choosing panels that maximize long-term power generation should be the priority, not choosing panels that minimize installation hassle.

After replacing my flexible panels with rigid ones, my daily power generation increased 40% immediately and has stayed consistent for three years. That extra power means more days boondocking, less generator runtime, and greater confidence that my batteries will recharge fully even in marginal conditions. That’s worth an afternoon of careful installation work.

Understanding how panel selection impacts overall system performance connects directly to choosing quality batteries and controllers that efficiently capture and store the power those panels generate throughout varied weather and seasonal conditions.